Info

Our vision of sustainability is encapsulated in our aim to evolve into a circular brand. This means that in all aspects of our operations, we look at how we can integrate sustainability and circularity principles. It's a continuous process of analyzing, adjusting, learning, and improving, in which we strive to be transparent about what we do and what we achieve. Together with our stakeholders, we evaluate the impact our company has and identify areas for improvement.

We've deliberately chosen not to prioritize specific sustainability initiatives. Instead, we've woven sustainability throughout our entire business operations, connecting it with distinct business strategies. For example, our sustainability principles in HR are integrated into the HR strategy. And our principles in the area of safety and health are included in our group Health & Safety strategy and rolled out from there. This approach enables us to actively address multiple themes simultaneously and make continual progress. This fits into our vision: sustainability is not a standalone theme. It encompasses all our business processes and is therefore an integral theme.

This is a crucial part of our sustainability pillar 'Our Solutions'. In our product design process, it's really important to think about sustainability and circularity and make smart choices. We have a clear product design process. From the beginning, when we set the product specifications, we ask questions about sustainability and circularity. For example, can we use recycled material? Where do we get components we don't make ourselves, and do those suppliers meet our criteria? In 2024, we're also going to start using Life Cycle Assessments in our product design process. This means that in the design phase, we look at the environmental impact of our new products. If we find ways to reduce that impact, we can do it before the product is made, rather than after.

In 2023, we started with a baseline measurement, using 2022 as our reference year. Every year, we gather new data and compare it to our reference year. In the meantime, we set targets on relevant KPIs, so that we can also communicate our progress each year.

There is a slight material premium for polypropylene. However, installers can expect labor savings of up to 70% due to quicker installation times.

InnoFlue® Polypropylene Special Gas Vent Systems have been sold in the United States and Canada since 2009. Polypropylene flue gas venting products have been sold throughout Europe for over 25 years. This technology has been proven to be safe and reliable. It is the dominating technology in Europe and is utilized by all European original heating equipment manufacturers.

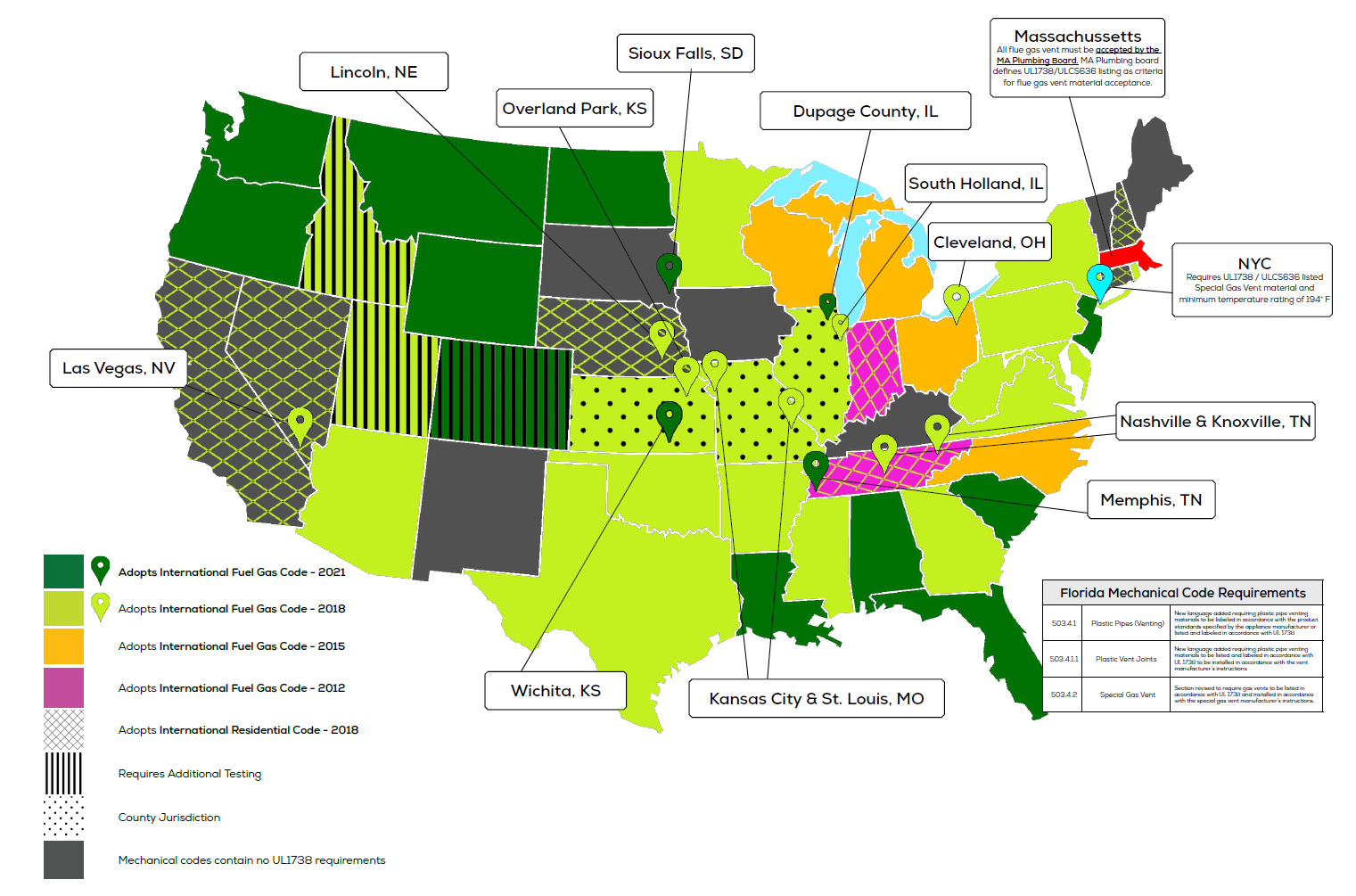

Yes. Centrotherm’s InnoFlue® is approved by the Massachusetts Plumbing Board for its intended use as a flue gas vent system.

No. PVC is not used as a flue gas vent system in Europe due to PVC’s lower maximum operating temperature, environmental health, and safety concerns.

InnoFlue® is readily available at numerous plumbing and HVAC suppliers throughout the United States and Canada.

Connector Rings are required for an installation of 2″ through 5″ diameter InnoFlue® to be UL-1738 and ULC-S636 compliant. Centrotherm strongly recommends the use of connector rings on all installations. Diameters 6″ and larger do not require the use of connector rings.

InnoFlue® Polypropylene Special Gas Vent Systems can be field cut to length using a hacksaw and miter box or equivalent. InnoFlue® must be cut on the male end of the pipe, preserving the socketed (female) end. After making a cut, the end can be beveled at the contractor’s discretion. The end must be deburred using a standard deburring tool or sand paper.

Yes, the exterior of InnoFlue® can be painted. Please follow the surface preparation specified by the paint manufacturer.

InnoFlue® is sold in effective lengths of 1′, 2′, 3′, 6′ and 10'. Effective length is the distance between the male end and the beginning of the female socket. Overall length includes the socket. When assembling/laying-out a system, always utilize the effective length.

- InnoFlue® SW Residential (diameters 2"-5") requires a slope of 1° or 1/4″ per foot.

- InnoFlue® SW Commercial (diameters 6"-12") requires a slope of 3° or 5/8″ per foot.

InnoFlue® Polypropylene Special Gas Vent Systems are a gasketed system and does not use any primers or glue. Slope ensures that acidic condensates do not come in contact with the gasket.

When venting combustion gas, InnoFlue® Flex cannot be installed horizontally. The installation of InnoFlue® Flex in a horizontal configuration allows for the pooling of condensate. This can create sagging in the vent system leading to the creation of back pressure. Back pressure can result in a forced shut down of the heating appliance.

InnoFlue® Flex and BlitzFlex® can be installed horizontally when used as an air intake.

InnoFlue® Flex and BlitzFlex® can be installed horizontally when used as an air intake.

InnoFlue® Flex can be installed in a shared chimney, assuming the flues are separated, if the ambient air temperature does not exceed 300°F (149°C).

InnoFlue® Flex should not be installed in a sheet rock wall.

InnoFlue® Polypropylene Special Gas Vent Systems can be installed in chases with offsets that do not exceed 45°. Chases can have multiple offsets.

No, InnoFlue® Flex is UL-1738 and ULC-S636 listed exclusively for use as a combustion gas vent system inside of a chase.

InnoFlue® Polypropylene Special Gas Vent Systems are commonly installed in masonry, b-vent and sheet rock chases.

InnoFlue® Concentric Polypropylene Special Gas Vent Systems incorporate combustion gas exhaust and air intake into a single system. This provides for aesthetically pleasing installation, a reduction in roof or wall penetrations and reduced labor time.

InnoFlue® Concentric is comprised of a metal outer and a polypropylene inner. Combustion air, or make up air, is pulled into the heating appliance through the space between the outer and inner pipes. Combustion gas is expelled through the polypropylene inner pipe.